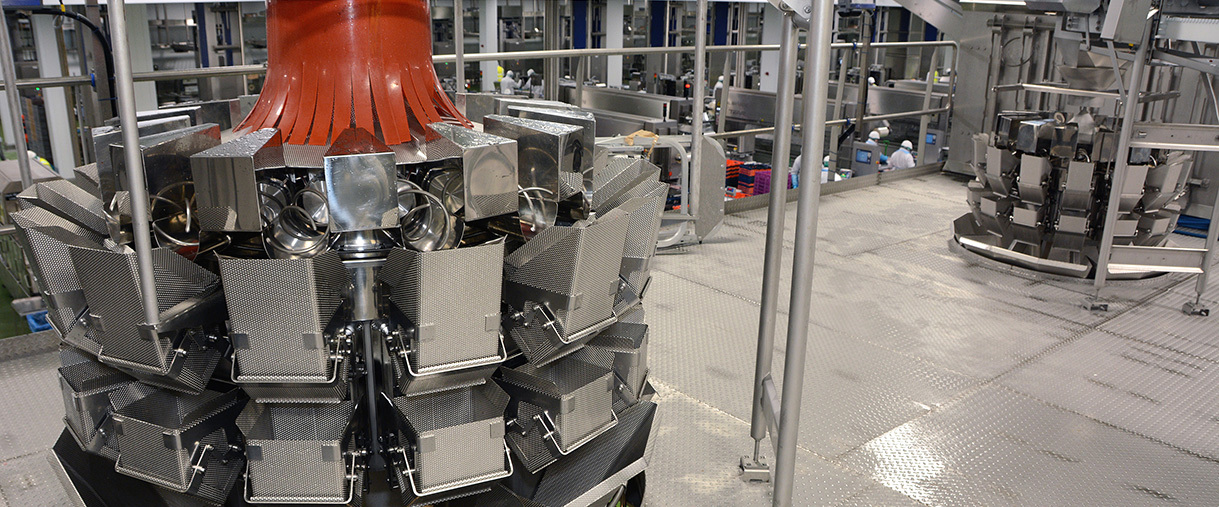

Flexible Ishida Systems Support Efficient Poultry Operation

Ishida Europe has installed a flexible and space efficient high-performance solution for the accurate weighing and packing of chicken legs and drumsticks at one of the UK’s leading food companies Faccenda Foods. Faccenda enjoys a reputation for innovation in the poultry industry. A key driver in the business is a commitment to continually seek ways to improve quality.

Facts and Figures

Flexible

The screwfeeder weigher features 2 litre hoppers with scraper gates that ensure effective product transfer of the sticky fillets.

Accurate

Product giveaway has been reduced by around 30%.

Efficient

Overall throughput has improved, with each operator now able to handle around 3.5 kilos of product per minute

Challenge

At Faccenda’s new state-of-the-art poultry processing plant in Telford, UK. A flexible and space saving solution was needed for weighing and packing chicken legs and drumsticks.

Solution

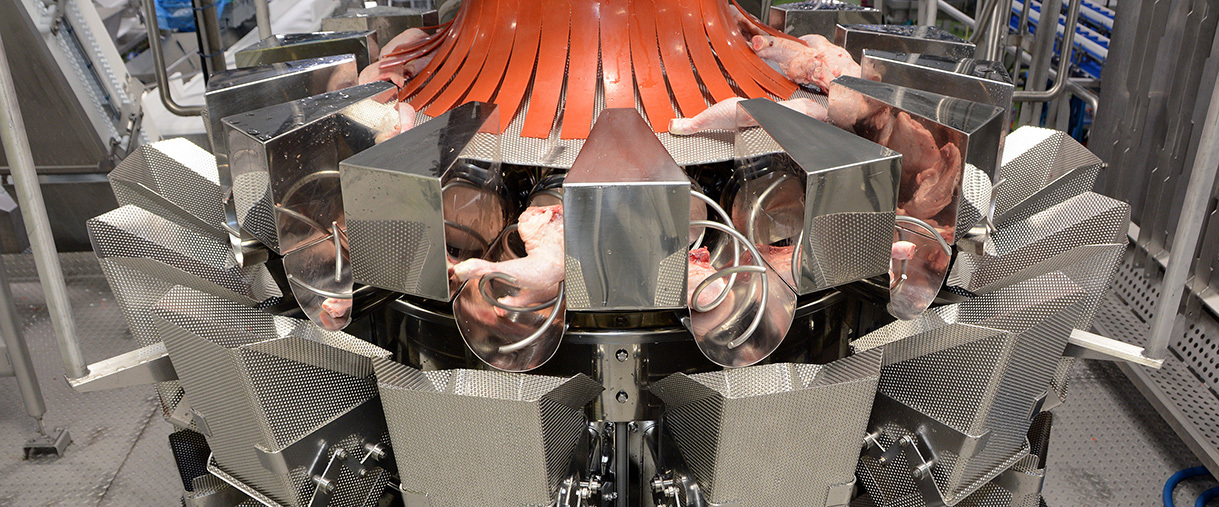

A second Ishida installation at Faccenda’s new state-of-the-art poultry portioning plant in Telford, UK, is weighing chicken fillets into trays which then pass through an Ishida Vision System and Seal Tester before being automatically picked and placed into crates via the Ishida IPS system.

Both systems utilise Ishida’s pioneering screwfeeder multihead weighing technology which features the familiar circular multihead weigher layout but incorporates rotating corkscrews to replace the traditionally-used radial feeders. The screws provide a powerful, controlled and fully automatic product feed to the hoppers. The weighers are combined with Ishida’s versatile Rotobatchers, with accurately weighed portions despatched to a series of packing stations on a batching table, where an operator places the product into a tray and styles it for effective presentation prior to the tray being sealed.

We have always been pleased with the performance and reliability of Ishida equipment but just as important for this project was Ishida’s ability to listen to our requirements and work with us to ensure we had the most effective solution.

A key benefit of the Ishida Screwfeeder and Rotobatcher combination is the fact that the Rotobatcher sits directly beneath the weigher. This maximises the use of space and has enabled Faccenda to create a highly efficient layout for its legs and drumstick operation with the four combinations placed closely together in a square configuration. This in turn provides the greatest flexibility for the packing operation, giving four different options depending on how the birds have been graded, with two of the screwfeeder weighers incorporating 5 litre hoppers to deal with whole legs and two weighers incorporating 3 litre hoppers for the smaller drumsticks.

Target weights for the legs and drumstick packs vary from 900g to 2.1kg. The new Ishida systems have replaced a belt grading and packing system to deliver a significant improvement in giveaway, which has been reduced by around 30%. Overall throughput has also been improved, with each operator now able to handle around 3.5 kilos of product per minute compared to 2.8 kilos with the previous system.

For the chicken fillet packing line, the screwfeeder weigher features 2 litre hoppers with scraper gates that ensure effective product transfer of the sticky fillets. Target weights are 500g to 765g with the line operating at around 40 packs per minute, well within the capabilities of the weigher.

Quality remains our overriding aim, we make the best use of automation to maximise our yields but this is never at the expense of quality.

Screwfeeder Weigher – Poultry

Ishida Screwfeeder Weigher for fresh sticky poulty.

As part of Faccenda’s stringent quality control procedures, the Ishida Vision System carries out a number of checks including label presence and position, that the label and date information are correct and the bar code readable. The Seal Tester applies gentle pressure to each tray to check the integrity of the seal. The Ishida IPS system provides a high speed pick and place operation to place the sealed trays into Eurocrates.

The £35 million factory at Telford is capable of processing up to 1.5 million whole birds per week, with the process from initial hanging to sealed pack taking just nine minutes. This is the result of a highly effective planning operation – the factory knows at least three hours in advance which products it will be running – combined with the latest automated equipment. A key benefit of the Ishida systems to this efficient operation is the fast changeovers that can be implemented with pre-set targets called up at the touch of a button on the remote control units.

Download case study

Speak to an Ishida expert

Every business has its own challenges; ours is to help you overcome yours. Working smarter, faster, together, we can help you achieve higher standards and get your products retail ready quicker.