Maximum bone detection.

Perfecting poultry inspection

- Precision accuracy.

- Greater efficiency.

- Easy integration.

- Less manual intervention.

Up to 60% more accurate than previous dual energy X-ray systems

In performance tests, the new IX-PD Series demonstrated near 100% detection rates for bones in a variety of products including chicken, diced meat and sausages. Increasing accuracy by up to 60% compared to previous dual energy x-ray systems for the detection of bone in chicken breast fillets. IX-PD demonstrates significant performance enhancement in products which overlap resulting in complex images.

Photon-counting technology for superior accuracy

The latest photon counting technology presents a revolution in X-ray systems. The enhanced resolution and ability to measure differing energy levels combined with the unique Ishida genetic algorithms optimise bone detection capability and minimise false positives.

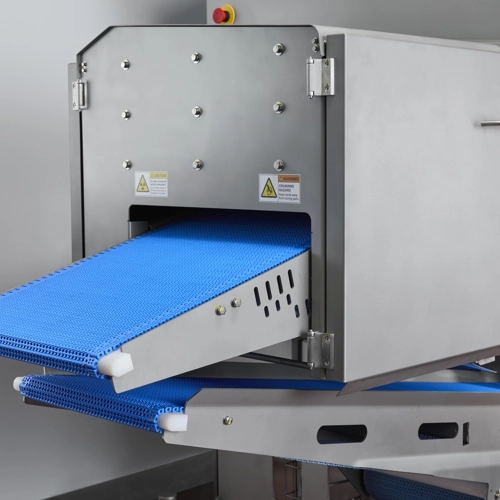

Recirculating conveyor for greater efficiency

Our recirculating conveyor makes rework easier and more efficient. When a bone or foreign object is

detected, the product is automatically recirculated back to the original operative to be reworked.

Compact dimensions for easy integration

The compact 450mm width of the IX-PD Series enables easy integration into new and existing packing lines.

Hygienic design for easy cleaning

Reduce downtime with our easy clean hygienic design including IP66-rated conveyor chamber, angled surfaces to prevent water build-up, tool-free belt removal, interlocked and removable curtain racks and an open frame design for rapid clean-down.

Lower total costs of ownership

Ask about our competitive X-ray purchase packages. We also offer low-cost service packages, including spares, maintenance, and repairs. Representing 3% of the TCO, you can spread the support costs over five years.