With both legislative requirements and retailer standards becoming ever more stringent and consumers less tolerant of product quality issues, it is vital that producers can demonstrate that they have taken appropriate food safety precautions. This is especially the case for foreign body contamination which can occur at various points during the production and packing process including from the supply chain, in process machinery, through personnel, or via the addition of non-dairy ingredients.

The Ishida White Paper, Dairy Production: Eliminating Foreign Body Contamination and Ensuring Brand Integrity, explains the importance of inline protection as part of an effective Food Safety Management System based on HACCP (Hazard Analysis and Critical Control Points) principles. It looks at the comparative benefits of the two main inspection and detection technologies – metal detection and x-ray inspection – and considers their application in two major dairy processing sectors, cheese and yoghurt.

“Any food contamination issue can have serious consequences, both immediate in terms of the financial implications of a recall and retailer fine, and longer term in the damage to brand reputation,” comments Ciaran Murphy, Ishida Europe’s Quality Control Business Manager.

“Whereas many retailers previously established very prescriptive Codes of Practice for suppliers, today the onus is much more on generating guidance documents and for food processors to demonstrate that they have adequate food safety risk assessment systems in place.”

“Our White Paper provides a clear overview of the issues, examines the options available and outlines the steps dairy processors should take in order to make the right decisions to meet their specific needs.”

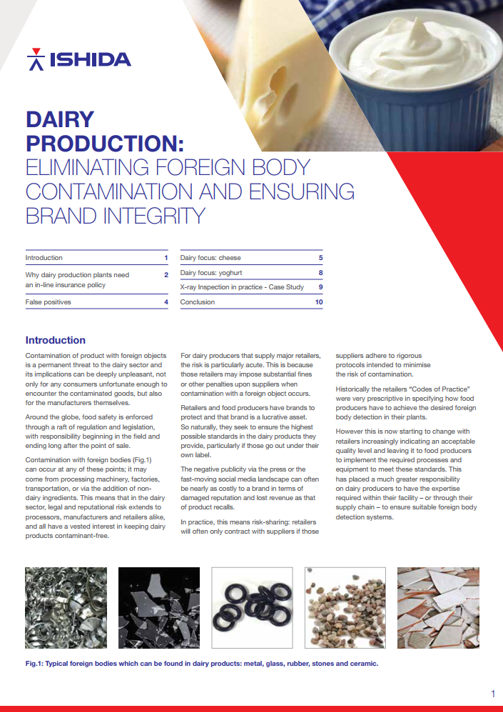

In addition to the White Paper, Ishida Europe has produced a series of informative videos that highlight the different foreign body and quality challenges that dairy processors can face – metal, rubber, glass, ceramic, and missed items and broken product. The videos can be viewed at https://youtu.be/_Dy_8i632Io

Ishida Europe also offers comprehensive demonstration facilities at its offices throughout Europe, the Middle East and Africa where customers can view the company’s ranges of quality control equipment and carry out specific tests to identify the most appropriate solution for their application.