For every challenge, there’s Ishida.

Turning questions into answers for 130 years

Want to cut food and packaging waste, and reduce costs? Find minute foreign objects and big performance gains? Discover smarter ways to significantly reduce product giveaway? We’ve been turning questions into answers for 130 years, which means we have all the product solutions, sector expertise and proven know-how you need. For every challenge, there’s Ishida.

Talk to usWhy Ishida?

The most important question and the one we answer every day. Providing more compelling reasons for you to put your trust in us.

- Full range of weighing, x-ray inspection, checkweighers, snacks packing, grading, tray sealing and leak detection equipment, plus supporting software.

- Built to the highest industry standards and powered by the latest technology, including advanced AI.

- Specialists in both food and non-food applications.

- Complete flexibility from a single machine to fully integrated line solutions.

- Solutions fully tailored to your sector and your products.

- Expert training online (remote), at your site or ours.

- Dedicated engineers on call 24/7/362.

Solutions for every sector

Whatever your sector or product, our proven tailored solutions resolve your unique challenges.

Snacks

We’re experts in snack packaging and can help you seal in greater output and consistency.

- Accurate weighing of multiple pack sizes to reduce giveaway

- Intelligent automated features minimise operator interventions, reducing downtime and waste

- Can handle the widest range of products, packs and films, including sustainable packaging

- Reliable detection of foreign bodies contaminants

- Maintaining shelf life through the best quality sealing for perfect pack integrity

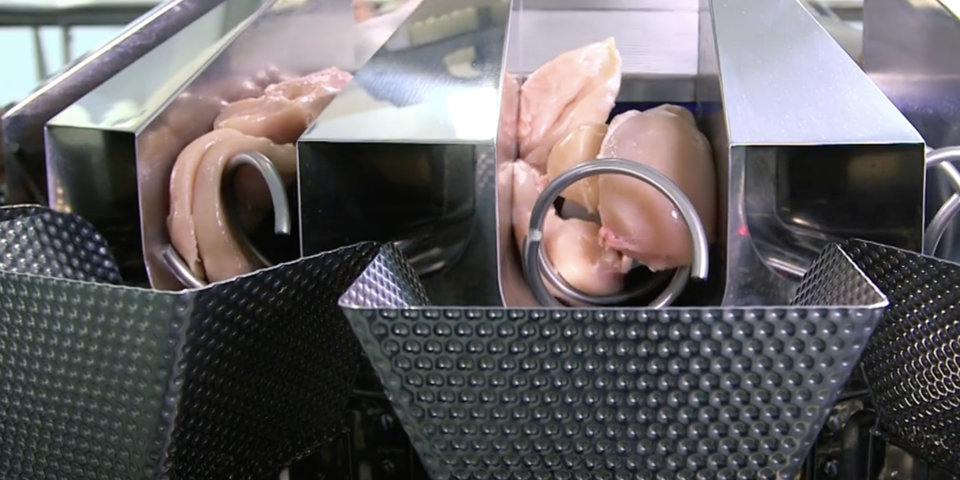

Protein

We are an experienced single source supplier of proven high-speed poultry line solutions.

- Maximising throughput and efficiency while reducing product giveaway

- Automating the handling of fresh, frozen “difficult to handle” sticky products

- Weighing, Grading and Batching solutions for maximum production efficiency and yield

- Maintaining shelf life through pack integrity

- Reliable detection of bones and other foreign bodies contaminants

Confectionery

Wrapped or unwrapped. Hard or jellied. You can trust our industry-leading solutions.

- Optimised weighing to reduce giveaway

- Minimising product damage

- High-speed weighing of both sticky and fragile products

- Achieving exact piece count at high speed

- Reliable detection of foreign bodies though X-ray inspection and metal detection Maintaining shelf life through perfect pack integrity and leak detection

Salads

Grow your output with our bespoke salad solutions, from multihead weighers to quality control equipment.

- Handling sticky, wet salad leaves at high speed

- Multihead weighers with IP69K waterproof rating

- Reliable detection of contaminants from stones to glass

- Maintaining shelf life through perfect pack integrity and leak detection on a variety of fresh produce

Frozen

Raise your performance in the lowest temperatures with our wide range of specialist frozen food solutions.

- Robust weighing technology withstands the impact of frozen products, providing solutions to plants with 24/7 operation, a vast product range and many product changeovers per day

- Designed to operate in wet environments, easily coping with harsh cleaning regimes

- Maintain optimum performance even at very low temperatures

- Consistent pack weights, minimum product giveaway

- Minimum downtime for cleaning and long-time reliability

- Reliable detection of foreign bodies though X-ray inspection and metal detection

Fresh

Fresh food needs great care – the kind of care only a true specialist can provide.

- Gentle weighing technology protects produce from bruising

- High-speed solutions accurately weigh and pack bulky produce

- Hygienic design for ready to eat products

- Inline leak detection to retain maximum freshness

- Easy to clean and maintain. Designed to operate in wet production environments, easily coping with harsh cleaning regimes

Ready meals

We understand the unique challenges of achieving the highest quality and consistency in ready meal production.

- Accurate, high-speed weighing and mixing of products to reduce giveaway at maximum capacity

- Maintaining shelf life through perfect pack integrity and leak detection

- Hygienic handling of wet and sticky products

- Reliable detection of foreign bodies though X-ray inspection and metal detection

- Integrated, single source solutions

Rising to every challenge means consistently pushing the boundaries of technology to provide faster, smarter, and more sustainable solutions. Here are just a few of our performance-enhancing innovations.

Inspired by innovation.

CCW-AS Multihead Weigher

Book a demo

Sentinel 5.0 Production Monitoring

Book a demo

IX-PD & IX-G2 X-Ray Inspection

Book a demo

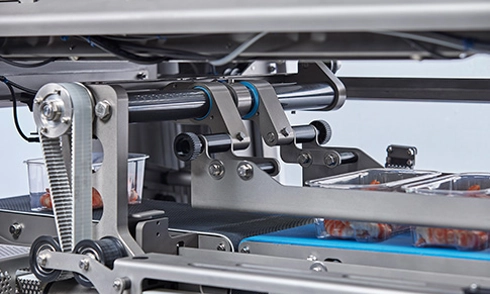

QX-500 (Tray Sealer)

Book a demo

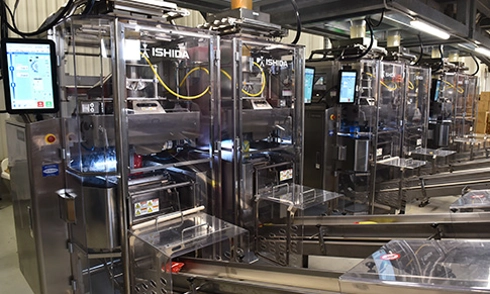

Inspira snacks bagmaker

Book a demo

Autosplice

Book a demo

Airscan Leak Detection System

Book a demo

DACS-GN Checkweighers

Book a demoFrequently Answered Questions

How can I save time and money?

Prevent expensive product recalls with our advanced quality control solutions, ensuring your products meet or exceed strict standards.

How can I harness the power of AI?

Sentinel 5.0 Production Monitoring is powered by advanced AI to unlock clearer insights and greater efficiency.

How easy is it to integrate Ishida solutions?

We provide fully integrated solutions designed to enhance the accuracy, speed and efficiency of your production and packing lines.

How can I save energy and be more sustainable?

Our equipment is designed to consume less energy, saving money and lowering your site’s carbon footprint.

Turn your questions into answers

Want to achieve greater weighing accuracy and consistency?

Increase production capacity while maintaining the highest quality?

Find minute foreign objects and big performance gains?

For every challenge, there’s Ishida.

Book your demo

Discover the power of connected technology for yourself. Get in touch to see how we’ve been turning questions into answers for 130 years.